Printed Circuit Boards (PCBs) are the foundation of most electronic devices and innovation nowadays. In the early 1900 s, we experienced the advancement of the first-ever printed circuit boards (PCBs) that altered how the electrical market utilized to work. With this creation, the expenses of the circuit board assembly were decreased and streamlined substantially. Today, these amazing innovations are the structure of practically all computational electronic devices and even easier gadgets such as digital clocks, calculators, and so on

The function of the PCBs is to supply a path to electrical signals from end to end to electronic devices, satisfying the gadget’s electrical and mechanical circuit requirements. As far as the developing and manufacturing of PCBs go, it is rather substantial for anybody associated with the electrical market. Since PCBs are accountable for passing the electrical energy through the elements linked to the board, it should be the very best quality.

MKTPCB makes some of the very best PCBs out there, and you can visit their site MKTPCB for more information. If you read this short article, I presume that you wish to find out how developing and manufacturing the PCBs go. We have actually discussed whatever in information listed below. If you are captivated to find out, make certain to have a look at this short article till completion.

A Guide to PCB Manufacturing Process:

Step 1: Creating the Design

First things initially, prior to you begin with the manufacturing procedure, you require to have a style of the board on hand. Get your finest designer to work for producing a design, to start with. Typically, computer system software application such as OrCAD, Altium Designer, Pads, KiCad, Eagle, to name a few, is utilized to produce the style. Be sure to inspect the information of both the internal and external links prior to settling the style.

Step 2: Printing the Design

Once you have actually picked your PCB style, the next action is to print it. For this, makers utilize a specific type of printer called a plotter. By utilizing this printer, picture movies of the PCBs are printed on the circuit boards. Unlike a basic laser jet printer, an extremely in-depth movie of the PCB style is offered utilizing the exceptionally exact printing innovation of Plotter.

Step 3: Making the Substrate

When the PCB starts to form, the procedure of making the substrate will begin forming too. The substrate is an insulating product which is accountable for holding the elements on the structure. The substrate product (epoxy resin and woven glass fiber) goes through an oven to be semicured. After travelling through the oven, the product is cut into big panels. These panels are then stacked in layers, and copper is pre-bonded to both sides. Lastly, the style from the printed movies is revealed once they are engraved away.

Step 4: Inner Layer Printing

Now, the style is printed to the laminate board, which is the substrate product. It functions as a body for getting the copper that structures thePCB A photo-sensitive movie covers the structure. It will line up the plans and the genuine print of the board. And to support the positioning procedure, holes are drilled into the PCB.

Step 5: Ultraviolet Light

After the positioning procedure, the withstand and laminate go through ultraviolet lights to solidify the photoresist. Now, to get rid of the additional photoresist, the board is cleaned with the alkaline option.

Step 5: Removing Unwanted Copper

Now, undesirable copper is eliminated with the assistance of a chemical option comparable to the alkaline option. This option will get rid of additional copper without hurting the solidified photoresist.

Step 6: Optical Inspection

After all the layers are tidy and all set, theyneed to be inspected for alignment Both the inner and outers layers will be associated the assistance of holes drilled previously. An optical punch maker drills a pin over the holes to keep layers lined up. After this, the evaluation procedure begins to ensure there are no flaws.

Step 7: Layer- up and Bond

In this action, the board takes the preferred shape. Now, the layers merely need combination. The external layer requires to accompany the substrate by means of layer-up and bonding. After this 2-step procedure, the layers will be sandwiched together.

Step 8: Drilling

Finally, holes are tired into the board utilizing a computer-guided drill to reveal the substrate and inner panels. After this action, the staying copper will be eliminated.

Step 9: Plating

After drilling, the board is all set to be plated. With the assistance of chemical services, all the layers will be merged. Next, the board is completely cleaned up utilizing another chemical option. These services will likewise supply a thin copper covering to the panel, settling into the drilled holes.

Step 10: Outer Layer Imaging

Again, a layer of photoresist will be used to the outdoors layer prior to the imaging procedure. Ultraviolet light will assist solidify the photoresist, eliminating the undesirable photoresist.

Step 11: Plating

Just like action 9, we will coat the panel with a thin layer of copper. Then the thin tin guard will be layered to the board to secure the copper of the outdoors layer.

Step 12: Final Etching

The undesirable copper will once again be eliminated utilizing the very same chemical option utilized prior to. At the very same time, the tin guard keeps the required copper safeguarded. This action will produce the PCB’s connections.

Step 13: Solder Mask Application

All the panels are cleaned up and covered with an epoxy solder mask ink prior to the solder mask is used on the board. The solder mask uses the green color, which is the normal color we see on the board. The undesirable solder mask is eliminated with ultraviolet light.

Step 14: Surface Finish

The PCB is plated with silver or gold to include additional solder-ability to the board, which will increase the bond of the solder.

Step 15: Silkscreening

It is the essential action because, in this procedure, vital info is printed on the board. Once it is done, the board will go through the last covering and treating phase.

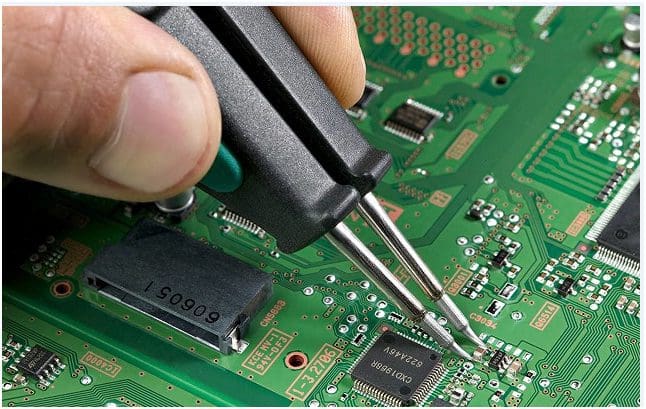

Step 16: Electrical Test

As a last action, a specialist will carry out an electrical test to guarantee the board works fine. The test will authorize the performance of the PCB.